| Polymer |

Melt

Temperature |

Defines

the

material manufacturer’s

recommended

temperature of the polymer as it exits the molding

machine through the nozzle and enters the mold. Minimum and

maximum

values define

the

manufacturer’s allowable range. |

| Polymer |

Mold

Temperature |

Defines

the

material manufacturer’s recommended temperature of the mold during

injection. Minimum and maximum values define the manufacturer’s

allowable range. |

| Polymer |

Ejection

Temperature |

Defines the temperature of the part when it has cooled down and is

ready for ejection. |

| Polymer |

Transition

Temperature |

Defines the temperature at which a polymer changes

from melted to solid state. For semicrystalline materials, this is a

precise temperature. For amorphous materials, the transition occurs

gradually over a range of temperatures, but is given as a single

value. |

| Polymer, and

Coolant |

Viscosity |

Defines a measure of a melted

polymer's

resistance to a flow. Highly viscous fluids, like peanut butter, resist

a flow much more than low viscosity fluids like water. Most polymers are

non-Newtonian, which means their viscosity is dependent on the shear

rate they experience.

Polymers

solidify as they cool, so their viscosity also depends on

temperature. |

| Polymer, and

Coolant |

PVT(pressure,

volume, temperature) |

Defines the relationship between pressure, volume,

and temperature parameters that evaluate how much a polymer

shrinks

as it cools from melted to solid state during the

injection molding process. |

| Polymer, and

Mold |

Solid

Density |

Defines the

mass-per-unit

volume of a material in its solid state. |

| Polymer,

Mold,

and Coolant. |

Specific

Heat |

Defines the amount of energy required to heat one

kilogram of a material by one Kelvin. |

| Polymer,

Mold,

and Coolant |

Thermal

Conductivity |

Defines a measure of how easily thermal energy can

transfer through a material. |

| Polymer,

Mold |

Elastic

Modulus |

Defines a

measure

of a

material's resistance to deform elastically under

stress application. More specifically, the ratio of tensile stress to

tensile strain (also known as Young's modulus). |

| Polymer,

Mold |

Poisson's

ratio |

Defines the ratio of transverse contraction strain to

longitudinal

extension

strain in the direction of

the

stretching force. |

| Polymer,

Mold |

Thermal Expansion

Coefficient |

Defines a measure of how a material expands and

contracts because of changes in temperature. |

| Polymer |

Shear Relaxation

Modulus |

Defines a measure of how a material relieves stress

over time when subjected to constant strain. |

| Polymer |

Curing

Model |

Describes the curing process for a thermoset

material. |

| Polymer |

No-Flow

Temperature |

Defines the temperature at which a polymer no longer

flows. |

| Polymer |

Melt Flow

Rate |

Defines a measure of the ease of flow of a melted

polymer. |

| Polymer |

%

Fiber |

Defines the percentage of fiber filler by

weight. |

| Polymer |

Max Shear

Rate |

Defines the material manufacturer’s maximum allowable

shear rate. |

| Polymer |

Max Shear

Stress |

Defines

the material

manufacturer’s maximum

allowable

shear stress. |

| Polymer |

Stress Optical

Coefficient |

Defines a measure of the amount of

birefringence

because of residual stress in a transparent polymer. Birefringence is

the optical property of a material having a refractive index that

depends on the polarization and propagation direction of

light.

|

| Polymer |

Leonov

Parameters |

Defines the parameters of the Leonov Viscoelastic

Model used to predict birefringence. Viscoelastic materials exhibit both

viscous and elastic behavior under stress. Material deformation is

temporary

when

the

stress is removed quickly,

but permanent when the stress is sustained. |

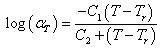

| Polymer |

WLF

Parameters |

Defines the Willams-Landel-Ferry (WLF)) equation

coefficients for the Leonov Viscoelastic Model. The WLF equation

is:  where T is the temperature, Tris a reference

temperature, and C1 and C2 are empirical

constants.

|

| Polymer, and

Mold |

Parallel Shear

Modulus |

Defines the in-plane ratio of shear stress to shear

strain. |

| Polymer |

Crystallization

Kinetics |

Defines a measure of the crystallization process of a

semicrystalline polymer that occurs between its melting point and

glass transition temperature.

|

| Polymer |

Juncture Loss

Coefficients |

Defines a measure of the hydraulic loss experienced

when a polymer flows through a significant change in cross-sectional

area, such as those common to a runner system. |

| Polymer |

Data

Source |

Defines the source of the data. |