| Using a Reference Plane |

A reference plane (or a planar face) defines two

directions in its plane and a third direction, which is normal to the

plane. The two directions in the plane are referred to as Plane dir 1 and Plane dir 2. They are parallel to the

boundaries of the plane, and assigned internally by the program. These

directions cannot be modified. When applying

restraints and loads, select Show

preview to identify Plane Dir 1 and Plane Dir 2. The

arrows of the load or restraint symbols point to the positive Plane

Dir 1, Plane Dir 2, and normal to the plane directions.

You can identify the normal direction by the

right-hand rule: thumb finger points to positive Plane Dir 1, index

finger points to positive Plane Dir 2, middle finger points to the

positive normal direction.

For material

properties directions, Dir 1 aligns with the X-dir, Dir 2 with the

Y-dir, and normal to the plane with the Z-dir.

|

| Using Front,

Right, and Top plane

as reference geometry. |

The table lists the direction

orientation with respect to the global coordinate system, when you

select one of the Front,

Right, or Top plane as

a reference geometry.

| Front

Plane |

Dir 1

aligns with the global X direction. Dir 2

aligns with the global Y direction.

Normal to the plane aligns with

the global Z direction.

|

| Right

Plane |

Dir 1 aligns with the

global Z direction. Dir 2 aligns with the

global Y direction.

Normal

to the plane aligns with the global X

direction.

|

| Top

Plane |

Dir 1 aligns with the

global X direction. Dir 2 aligns with the

global Z direction.

Normal

to the plane aligns with the global Y

direction.

|

|

| Coordinate Systems |

A coordinate system defines 3

directions, X, Y, and Z. The default coordinate system used by the

software, called the global coordinate system, is based on Plane1

(Front Plane). The origin of the global

coordinate system is located at the origin of the part or assembly.

Plane1 is the top reference plane that appears in the FeatureManager

design tree. The reference triad shows the global X-, Y-, and

Z-directions. All other coordinate systems are referred to as local

coordinate systems. You can define a local coordinate

system with .

|

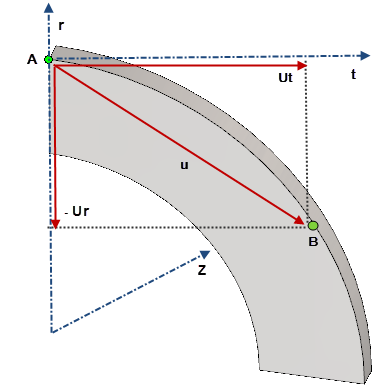

| Using a Reference Axis |

A reference axis defines a radial

direction, a circumferential direction, and an axial direction. When

applying restraints and loads, select the Show preview check box in the PropertyManager to

identify the positive directions. Use negative values for the opposite

direction.When specifying a circumferential

translation, you specify an angle (Θ) in radians. This sets the

translation in the circumferential direction (v) to: v = r.Θ, where

r is the radius of the node at which the restraint is applied

relative to the reference axis.

When viewing deformation results with respect to a reference axis, the

displacement vectors are reported as Ur,

Ut, and UZ, where r represents the

radial direction, t the tangential direction, and z the

axial direction. This r- t -z system is with respect to each

node’s original configuration.

Taking a quarter ring as an example, suppose that a node A is displaced

from its original position to point B and the displacement

vector at the end of a nonlinear solution is defined by u.

The program reports for the radial displacement

Ur a negative value in node A’s original

radial direction and for the tangential direction a positive

value Ut in node A’s original tangential

direction. Note that Ur does not necessarily

indicate an expansion (or contraction) of the ring and

Ut does not indicate a rotation of the ring

as well.

|

| Using a Cylindrical Face |

This is similar to using a reference

axis. The axis of the cylindrical face is used as the reference axis.

|

| Using a Straight Edge |

A straight edge defines one direction.

When applying restraints and loads, select the Show preview check box in the

PropertyManager to identify the positive direction. |