The Fill Settings define the injection molding process parameters such as

Filling Time, Melt

Temperature

Mold Temperature, and Injection Pressure Limit.

To open the Fill

Settings PropertyManager:

- In the PlasticsManager, expand Process Parameters, and click Fill

Settings.

Process Parameters

|

Filling Time

|

Specifies the time it takes the molten plastic to fully

fill the cavity. The program calculates

automatically the Filling

Time based on the part geometry and the

properties of the material you select.

Click Auto

to enable

editing of the Filling

Time. to enable

editing of the Filling

Time.

If you use the

Advanced options

below to control the filling process, the software recalculates

the Filling

Time.

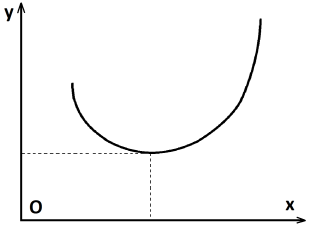

The diagram shows the

variation of injection pressure (y-axis) with respect to filling

time (x-axis). The U-shape diagram indicates that the optimal

filling time is located at the bottom of the curve. For short or

very long filling times, higher injection pressure values are

required.

|

| Melt

Temperature(oC) |

Specifies the temperature of the polymer at the

injection location (or locations). The default

value for Melt

Temperature is taken from the material database

(see Polymer-Material

Parameters tab of the selected material).

Click Reset

to reset the

Melt Temperature to

its default value. to reset the

Melt Temperature to

its default value.

|

|

Mold Temperature(oC) |

Specifies the temperature that the mold is heated to. The default value for Mold Temperature is taken from

the material database.

Click Reset

to reset the

Mold Temperature to

its default value. to reset the

Mold Temperature to

its default value.

If the

mold temperature is not constant but varies with time,

select Mold Temperature

profile to enter the mold temperature

data.

|

| Injection Pressure Limit |

Specifies the maximum allowed value of the pressure of

the polymer at the injection location (or locations). If the pressure reaches the Injection Pressure Limit value,

the inlet flow rate automatically reduces to a value

corresponding to this limit, and the Filling Time is longer than the

Filling Time value that is set.

You can adjust the default Injection Pressure Limit

according to the capacity of your machine.

Click Reset

to reset the

Injection Pressure

Limit to its default value. to reset the

Injection Pressure

Limit to its default value.

|

| Clamp

Force Limit |

Specifies the maximum allowed value of the force required to keep the

mold closed. If the force reaches the Clamp Force Limit value, a

warning alerts you in the Analysis Manager, and the analysis

continues unimpeded.

You can adjust the default Clamp Force Limit according to

the capacity of your machine.

|

Advanced

| |

Flow/Pack Switch

Point

(% Filled

Volume)

|

Controls the process changes from FLOW to PACK. During FLOW, polymer is forced into

the cavity at a given flow rate, regardless of pressure. To

avoid a rapid pressure rise and potential damage to the machine,

it is common to switch from FLOW to PACK just before the cavity

becomes full, for example at 95% of the cavity

volume.

|

| |

Temperature Criteria for Short Shots(oC) |

If the temperature in the molten polymer is

below this temperature value, a warning alerts you in the

AnalysisManager.

If the temperature stays below this value for

several iteration steps, a short-shot occurs. The polymer

solidifies and the melt flow stops.

|

| |

Multi general Gate Flow-rate/Press

control

|

Available for shell

analysis

procedure only and multiple injection locations.

|

Equivalent

|

Distributes equal flow rates at each

injection location, with potentially different resulting

pressures.

|

|

Automatic

|

Balances the flow between injection

locations to produce equal pressures, simulating the

effect of a runner system.

|

|

| |

Gravity Direction: (Global) |

Defines the direction of gravity. For example, if the model is oriented in the injection molding

machine such that the positive Y- axis points upward, select the

negative Y- axis for the gravity

direction.

Gravity Direction is

available for the solid analysis procedure.

|

|

Flow Rate Profile Settings

|

Controls the flow rate during the

filling of the cavity by defining a Flow

Rate Profile based either on volume or time

control. |

| |

Volume control (Absolute control)/Base on machine max flow

rate |

You can control the variation of

Flow rate or Screw speed in terms of the

percentage of filled cavity volume, or the screw position. By

default you can enter five data pairs. You can increase the number

of data pairs in Section num.

|

Flow rate (cc/sec) or (in3/sec)

|

Specifies the volumetric flow rate.

|

|

Flow rate (%)

|

Specifies the flow rate as a percentage

of the Reference flow

rate. For example, if the Reference flow rate

(cc/sec) is 350, and you enter a

flow

rate of 80%, then the actual flow rate is 280 cc /

sec.

|

|

Screw speed

|

Used together with the Screw diameter to

calculate the flow rate (flow rate = Screw speed * Screw

section Area).

|

|

Screw position

|

Used together with the Initial screw position

to define the volume of material delivered to the

cavity.

|

|

Volume (%)

|

The percentage of the filled cavity

volume.

Enter

a value of 100% in the last table entry.

|

- Specify an Initial screw

position, if the Flow

Rate depends on the screw position.

- Specify a Reference flow rate (cc/s), if you

define the flow rate as a percentage of the reference

flow rate.

- Specify a Screw diameter, if the flow rate

depends on the screw speed.

|

| |

Time

control (Relative control)/Base on filling

time |

Specifies

the profile of a relative flow rate versus the filling time or a

percentage of the total filling time.

|

Filling Time (sec)

|

Displays the filling time from the

Fill

Settings PropertyManager. You can enter

the filling time profile data in absolute (Time sec) or relative

values (Time

%).

|

|

Flow rate (%)

|

The Flow

Rate (%) values you enter in the table

are interpreted relative to each other. For example, if

two data points are defined with Flow Rate values of 10%

and 30%, the flow rate for the second data point

is

three times larger than the first flow rate value.

The

software calculates the actual

volumetric flow rates for each data point to satisfy the

given relative profile and the filling time for the

cavity.

|

|

| |

Apply |

Applies the current settings to the current of

the flow rate profile.

|

|

Machine Database

|

From the injection molding machine database, select an

injection machine. The injection molding machine database is

provided as a reference only. The selection of any machine does

not have any effect on the analysis settings or results. If you

want to use any data from the machine database, enter the data

into the Analysis Process parameters.

When you select a machine from the database, you

need to copy the selected machine's parameters in the respective

Fill Settings

PropertyManager input fields. The software does not transfer the

selected machine's default values for Injection Pressure Limit,

Screw Diameter

(Flow Rate Profile

Settings dialog box), and Reference Injection Rate

(Flow Rate Profile

Settings dialog box)

automatically.

|

| |

Viscoelastic Birefringence Calculation

|

Activates the Birefringence

calculation.

Select

a polymer

that

includes definitions for the Birefringence material parameters to

use this feature.

These material parameters are the Leonov

parameters in the Material Database / Polymer-Material

Parameters.

|

Solver Settings

|

Options

|

Provides access to the advanced solver settings.

Accept the default values of the solver settings to produce the best

results over a wide range of cases. For most analyses, you do not

need to modify the solver settings. See topic Advanced

Settings for the Flow/Pack Solver.

|

Fiber Orientation Calculation

To improve the strength and performance of plastic products, many

plastics contain fibers. The fiber percentage of each material is included in the

polymer material database. Material data, such as viscosity coefficients, reflect

the properties of a particular fiber % and polymer combination.

During cavity filling, the fibers become oriented along the flow

directions. This produces changes in the microstructure that affect the mechanical

properties and final dimensions of the product.

For polymer materials that have a % fiber value, select Fiber Orientation Calculation to compute fiber

orientations during the simulation.

|

Current % Fiber based on

Weight

|

Specifies

the percentage of fiber in the material based on weight. For example: for 1 kg material with 200 gr of

fiber, you enter 20 (%) for Current

% Fiber based on Weight;

If

you select a polymer from the Material Database, the fiber

percentage value is taken from the

database.

|

Co-injection

In a co-injection simulation, the machine injects two polymers (or a

polymer and a gas) sequentially into the cavity. Typically, the first material

becomes skin and the second material fills the core. Co-injection is also used for

Gas Assist injection molding,

where you

select a gas for the second

material,

and the part becomes hollow.

In the material dialog box,

select , and select the second material from the plastics database.

|

2nd Material Melt

Temperature

|

The default value is taken from the material

database (see Polymer-Material

Parameters tab of the selected material data

sheet).

|

Venting Analysis

In general, the presence of air in the cavity is ignored during simulation.

However, venting analysis allows you to include the effect of the air, and the

pressure that it may exert on the melt front.

If you run venting analysis, you must define vent locations in the

cavity (see ). Venting analysis identifies and tracks bubbles that may form and

coalesce in the cavity away from air vents and computes the pressure that develops

in them.

For the first analysis, it is recommended to not define any air vents. Use the

Venting Pressure result to guide air vent placement, and

avoid placing them where they are not required.

| Cavity Initial Air Pressure (MPa)

|

The initial air pressure when the cavity is empty is

14.71 psi or 0.1 MPa by default. |

| Cavity Initial Air Temperature () |

The initial air temperature in

the cavity is the room temperature by default. |

Mold-Melt Heat Transfer Coefficient

The heat transfer between the polymer and the mold walls varies

during the different stages of the injection process:

- During the filling stage, the polymer enters the cavity,

and the heat transfer raises to the maximum value.

- During the packing stage, the polymer is in contact with

the mold walls, and the heat transfer stays at the maximum value.

- During the ejection stage, the polymer shrinks during the

pre- cooling time, and detaches partially from the mold walls. The heat

transfer is reduced in this stage.

Reactive Control Type

Available only when you select a thermoset polymer material. Examples of

thermoset material families available in the Plastics database include: BMC, EMC,

and LSR.

In thermoset injection molding, the plastic in a liquid state (typically at room

temperature or colder) is injected into a heated mold. The heat from the mold

induces a chemical reaction that creates cross-links (permanent connections between

molecular chains) in a process known as curing. Choose between two different options

to determine the duration of the analysis.

| Conversion |

When selected, the Fill/Pack stage lasts until

the analysis reaches the specified value for the Reactive Eject Conversion:

(%).

|

| Time |

When selected, you explicitly define the

duration of the Fill and Pack phases. At the end of the analysis,

you can review the curing conversion % to better understand whether

your specification is appropriate. |

| Reactive Eject

Conversion: (%) |

Specifies the required conversion degree.

Available when you select Conversion. |

Mold Temperature Profile

If the mold temperature is not constant but varies with time,

select Mold Temperature profile.

Enter the mold temperature variation in terms of absolute time or as

a percentage of the total process time. The total process time includes Fill, Pack,

and Cool time.

For a more detailed consideration of mold temperature, you can perform a

Cool simulation, where heat transfer

between the cavity, mold, and cooling channels is computed. These results provide

temperatures that vary both in location and in time. These Cool

simulation results override any values you enter for Mold Temperature and Mold Temperature

Profile.

|

Edit/Show Profile

|

Select to

define

the mold temperature profile during the injection process. Enter the

values of mold temperature versus time (in seconds or in percentage

values of the total process time). |