The Solid analysis procedure requires a solid

mesh. A solid mesh is appropriate for thick parts and models with complex

geometry.

You can create three types of solid meshes:

- Tetrahedral Hybrid

- Hexahedral

- Automatic

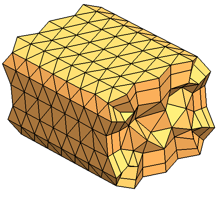

Tetrahedral Hybrid

The tetrahedral hybrid mesh type uses a triangular surface mesh as a basis

for creating tetrahedral volume elements, generally combined with boundary layers.

Boundary layers are layers of prismatic elements at the surface of the body. When

you span gaps that are small relative to the local surface mesh size, a prismatic

element is better able to maintain a high-quality, less-distorted shape than a

tetrahedral element. In general, for thin gaps you need 5 boundary layers of

prismatic elements to get accurate and robust flow solutions. By default, the

software creates 2 boundary layers.

|

| Example: Hybrid tetrahedral mesh |

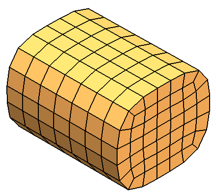

Hexahedral

The hexahedral mesh type uses nonorthogonal hexahedral elements to fill the

volume of a domain. In regions where the software cannot create hexahedral elements

of sufficiently high quality, the software instead creates tetrahedral elements.

Hexahedral elements, when aligned with the part cavity (and hence the melt

flow) can potentially deliver more accurate and efficient solutions. However, the

hexahedral mesh type might not be suited to all shapes. The software first creates a

triangular surface mesh as a preprocessing step, and then bases the hexahedral

meshing on this surface mesh rather than the part geometry. This extra step

introduces a potential source of error in terms of approximation to the original

geometry.

|

| Example: Hexahedral mesh |

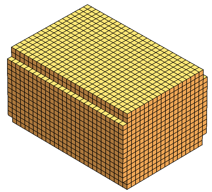

Automatic

The Automatic mesh type is the

fastest way to create a mesh with minimum user intervention. The software assigns a

mesh size based on the part dimensions, and applies a curvature-based refinement to

capture small features. Where possible, the software creates a tetrahedral hybrid

mesh. If meshing fails because of geometry issues, such as non-manifold edges or

gaps between surfaces in the model, the software creates a Cartesian voxel mesh.

Use the Automatic mesh option for

rapid analysis. Be cautious because the voxel mesh cannot always accurately

represent the geometry. For accurate analysis, use the Tetrahedral Hybrid or Hexahedral mesh types.

|

| Example: Voxel mesh. In this case, the software

failed to create a hybrid tetrahedral mesh. |