Distributed coupling allows the faces attached to pin and bolt connectors

to deform, which delivers a more realistic representation of a connector’s behavior.

When you set Connection Type to

Distributed, a distributed coupling

formulation connects a reference node (beam element node of a bolt shank) to a group of

coupling nodes inside the imprint regions of a bolt's head and nut. Distributing

coupling constrains the motion of the coupling nodes to the translation and rotation of

the reference node. Nodes located inside the head and nut imprint areas can deform

relative to each other.

This constraint is enforced in an average sense in a way that enables control of the

transmission of loads through weight factors at the coupling nodes. For example, the

constraint distributes a bolt's pre-load such that the sum of the forces at the coupling

nodes is equivalent to the total pre-load at the reference node. Uniform weight factors

are applied in this case.

The distributed connection produces more realistic stress and

displacement fields at a bolt's head and nut contact areas.

A rigid connection produces stress hot spot areas inside the head and nut

regions of the connected components, because rigid bars introduce high stiffnesses. A

distributed connection eliminates these high stresses.

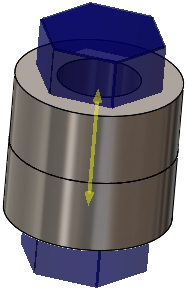

The image shows two cylindrical components connected by a bolt with a

prestress load of 1,000 N. No-penetration contact exists between the two

components.