| Configuration name |

The name of the geometry configuration used to create

the mesh. |

| Mesh type |

Solid or

Shell |

| Meshing method |

Manual or

Automatic |

| Triangle size |

Global triangle size used for the mesh creation.

Locally, the triangle size may be finer than this due to refinement

based on curvature or local geometry entity selection. |

| Mesh tolerance |

The minimum allowable element size for automatic

refinement is given by the default value of triangle size multiplied

by the value of mesh tolerance. Mesh Tolerance is visible only

when you apply Curvature-based refinement.

|

| Total nodes of surface

mesh |

The total number of nodes (mesh vertices) of the

surface mesh. |

| Total elements of surface

mesh |

The total number of elements (mesh faces) of the

surface mesh. |

| Total nodes of solid

mesh |

The total number of nodes (mesh vertices) of the

solid mesh. |

| Total elements of solid

mesh |

The total number of polyhedral elements of the

solid mesh. |

|

Waterproof

|

|

Yes

|

The surface mesh is waterproof with no holes.

|

|

No

|

The surface mesh contains free edges.

|

|

| Number of Mesh

Group

|

Identifies the number of distinct meshed domains in a

model. For example, if you identified a geometric

body as a cavity and you add a runner, the number of mesh groups

is two. You can have two mesh groups for a single part when the

part has two distinct bodies that are not merged.

|

| Element

Intersections

|

Identifies where elements overlap. The software fails

to create a solid mesh when intersection elements exist. |

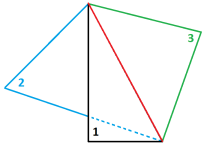

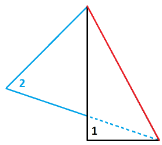

| Non-manifold |

Identifies elements that share a boundary with more

than two elements.

|

|

| Non-manifold elements. Three triangles share a

common edge (red). |

Manifold

elements. Two triangles share a common edge

(red). |

|

| Bad Elements

|

Shows the percentage of distorted elements with poor

aspect ratios over the total number of mesh elements. Elements with an aspect ratio between 8 and 20

are characterized as Bad

Elements.

Consider fixing

these elements, especially when the percentage number exceeds

15.

|

| Very Bad

Elements |

Shows the percentage of very bad

elements over the total number of mesh elements. Elements with an aspect ratio above 20 are characterized as

Very Bad Elements.

|

| Maximum Aspect

Ratio |

Shows the maximum aspect ratio in a model. The aspect ratio of an element is the ratio of

the longest edge to the shortest edge of a triangle. By

definition, the aspect ratio of a perfect triangle element is

1.0. A higher aspect ratio indicates poorer element

quality.

|

| Unmatched

Elements |

Identifies elements at the boundaries of geometric

entities that touch or intersect but do not share common nodes. In

these cases, the mesh is considered incompatible due to unmatched

elements. Such errors are common with insert molding or overmolding

where two domains meet. In compatible meshes, the

entities that touch have a node-to-node correspondence between

their meshes at the boundaries.

|

| Computer name

|

The name of the computer that generated the

mesh. |