When a symbol is inserted on a wire, the wire is automatically cut on the right of

the symbol. In the same way, when the wire is placed over the symbol, it is automatically cut.

This is only possible if the symbol has connection points.

The connection points are placed so that they are superimposed on the wire when the

symbol is inserted. The connection points have an attribute allowing the number of

the manufacturer part material terminal to be propagated.

To access connection point, in the menu click

.

.

There are three types of connection points:

- Connection point (By default). A connection point

used for all symbols other than polarity origin-destination.

- Incoming/outgoing connection point. These connection

points are directional (incoming / outgoing) and exclusively reserved for

symbols used for polarity origin-destination.

When inserting connection points, ensure that the SNAP option

is active and the resolution pitch is compatible with the distance separating the

symbol's circuits, as well as the distance separating two wires (Example: two phases

of a power wire).

The connection points are positioned where the symbol must cut the wire.

To insert a connection point:

- Select the circuit that the connection point belongs to in the dockable

panel.

- Select the command in the menu.

- Turn the connection point in the right direction (press Spacebar

on the keyboard to rotate the connection point according to the

angle of the wire).

- Click the insertion point for the connection point in the graphical

area.

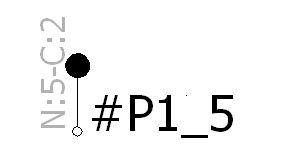

A message appears informing you when the connection point has been inserted

(

N:0-C:0). The number after the

C

is the circuit number. The number after the

N is the order

number in the circuit.

The value allocated to N is not important; you can have

N:6 even if the circuit has only two connection points.

All values for N for a given circuit must be compared. The

program then classifies all the connection points for the circuit according to the

value of N.

For a circuit C1, you can have N:1 and

N:4. N:1 is the first connection

point in the circuit, and N:4 is the second. When the

manufacturer part is allocated, the same principle is used when allocating the

numbers on the material terminal. The number of the first material terminal will be

allocated to the first connection point on the circuit. The number of the second

material terminal will be allocated to the second connection point on the circuit,

and so on, for all the component's circuits.

A termination type can be associated with the connection point of the symbol, but if

you assign a manufacturer part on this symbol, the termination type of the

manufacturer part will be applied.

A contextual menu allows you to edit an existing connection point.

Multiple Connection Points

To access multiple connection point, in the menu click

.

.

This command is similar to the connection point command except that circuits can be

created simultaneously, helping you place all connection points after

definition.

A dialog box opens that lets you add the circuits that belong to the symbol.

| |

|

Add

|

Adds the circuits. |

Delete

|

Deletes the selected circuits. |

Initialize from manufacturer

part

|

Selects a manufacturer part with its circuit definition. This

manufacturer part can be associated with the symbol. |

Add the circuit type and indicate the quantity in the Number of

circuits field. Enter the number of terminals on the component, as

well as for each circuit. This data is automatically entered if you select a

manufacturer part. Click OK to confirm and exit the dialog

box.

The connection point is attached to the cursor. The connection points are placed one

after the other, according to the dockable panel instructions.