You

can use pin connectors to simulate the behavior of pins in an assembly without modeling the

actual pin

geometries.

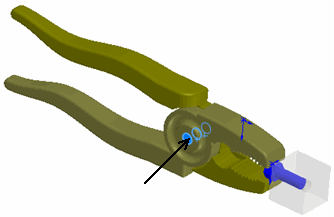

An assembly consists of multiple parts connected to each other with pins,

bolts, screws, or springs. Examples of assemblies with pins include laptops, scissors lifts,

pliers, and actuators. To simulate such assemblies, traditionally, you would need to create

each pin geometry and apply contact conditions between the pins and their contacting faces.

This is a computationally expensive approach.

In

applications

where

you

want to know the

effects of pins on adjacent

parts

rather

than the stress distribution

of

the pins themselves,

use

pin connectors to

simulate

the behavior of the

pins.

You can define a single pin connector attached to multiple coaxial

cylindrical

faces or

shell

edges

(maximum of

10

selections).

In the Connector-Pin PropertyManager,

for Cylindrical Faces/Edges

, select all coaxial cylindrical faces (or

edges) that are attached to the pin (maximum of ten). The selected cylindrical faces or

circular edges can belong to one body or to several bodies.

, select all coaxial cylindrical faces (or

edges) that are attached to the pin (maximum of ten). The selected cylindrical faces or

circular edges can belong to one body or to several bodies.

When to Use Pin Connectors

|

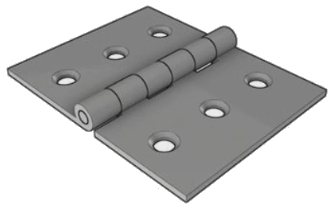

Define

one pin connector that acts as a hinge to connect the three

plates. |

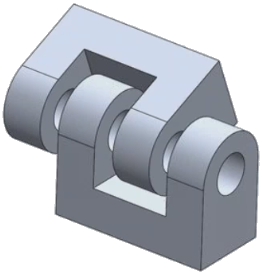

|

Define a pin connector to connect the two

cylindrical faces that rotate against each other. Allow the cylindrical faces to

rotate against the pin, but prevent them from moving axially with respect to each

other. |

|

Define one pin connector to connect the six

cylinders of the hinged plate. |

|

Define

a pin to connect the two rotating parts. One pin connector attaches to four

cylindrical faces. |