After running a Warp analysis, you can view deformation plots of the part

because of stresses that develop during filling and packing, and stresses because of thermal

contraction after the part has fully cooled.

To open the Warp

Results PropertyManager, do one of the following:

- In the PlasticsManager tree, expand Results, and double-click Warp

Results.

- In the SOLIDWORKS Plastics CommandManager, click Warp Results.

Available Results

| Total Stress Displacement

|

Shows the total deformation of the part after it is

molded and cooled to room temperature. All simulated stresses and

thermal effects are considered in this result. |

| In-mold Residual Stress

Displacement

|

Shows the portion of the deformation because of stress

that develops during fill, pack, and in-mold cool stages. This

stress includes the effects of nonuniform cooling and freezing while

the part is in the mold. |

| Quenching Thermal Stress

Displacement

|

Shows the portion of the deformation that develops

after the de-molding stage, because of the stress associated with

thermal contraction as the part is cooled to room temperature. |

| Total Stress Displacement

(orientation effect) |

Shows an estimate of the total deformation of the part

caused by anisotropy from the orientation of fillers in the

material, such as short glass fibers or carbon fibers. For materials without any fillers, this

deformation is negligible.

|

| Sink-Mark

Profile

|

Shows the depth of sink marks after the part has been

ejected and cooled to room temperature. All thermal stresses and

warping effects are included in this result. |

| In-mold Residual von

Mises Stress |

Shows the magnitude of the residual von Mises stress

inside the part at the end of the in-mold cooling time. |

| De-molding Residual von

Mises Stress |

Shows the magnitude of the residual stress that remains

after the part cools to room temperature, and allowed to deform

freely. |

Advanced

Available for displacement results. These controls affect only the color display of the plot. The deformed shape that is displayed always respects the sign (positive or negative) of the displacement result.

|

|

| Displacement Plot Z-direction - Direct

Value |

Displacement Plot Z-direction - Absolute

Value |

Deformation Scale

Available for displacement results.

| Scale |

Magnifies the deformation results.

This is very useful for inspecting warped shapes with tiny

deformations. A Deformation Scale of 1.0

shows the actual deformation. |

Set Reference

Available for displacement results. These controls modify the reference location and orientation used to compute displacement results. Setting a reference can be useful in comparing displacements with those that you measure after placing the part in a checking fixture or jig.

| Based on origin

|

Selects a location on the model as the baseline of

deformation by selecting a node on the model. A glyph is displayed

on the selected origin. Enter 0 in the box to use the default

global origin.

|

| Based on plane

|

Selects three nodes, which define a reference

plane. The deformed part is reoriented such that these three

nodes remain in the reference plane that they define.

|

First Reference

|

Select the first node and click

Apply. This is the origin of

the reference system.

|

|

Second Reference

|

Select the second node, and click

Apply.

|

|

Third Reference

|

Select the third node, and click

Apply.

|

|

| Apply

|

Applies the selected

reference. |

| Reset

|

Resets the reference back to the

default global origin. |

| Fix Reference

Origin |

Adjusts the orientation of the

model to the displayed orientation. |

|

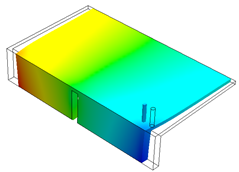

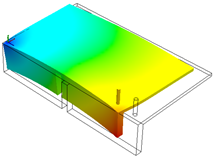

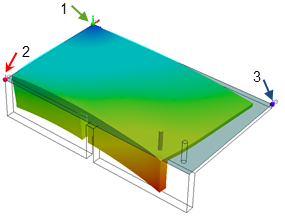

| Displacement plot based on default global origin. |

|

|

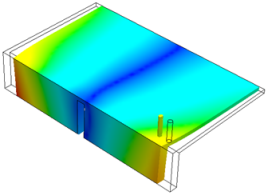

| Displacement plot based on origin selected on the left corner. |

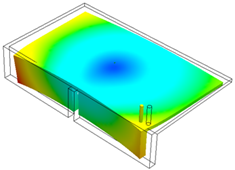

Displacement plot based on a reference plane defined by three

corner nodes. |

Clipping Options

| Clipping Plane

Mode

|

Available for Solid Mesh. Allows

for visualization of results inside the part. Creates a section

view of the selected contour plot.

Select

a plane or a planar face of the model to create a clipping plane

parallel to the selected entity. Select a curved face of the

model to create a clipping plane tangential to the selected

entity. You can adjust the position of a clipping plane by

dragging the arrow symbol.

|

Clipping Plane

|

You can switch between existing

clipping planes.

If you have not explicitly created

any new clipping planes, the default clipping plane

New Clipping

Plane is available. The orientation of

the default New Clipping

Plane is parallel to the Y-Z plane,

and is positioned in the middle of the X-axis.

You can change the orientation of

each plane in (PlasticsManager tree).

|

|

Flip Normal

|

Flips the direction of the vector

normal to the clipping plane.

|

|

Offset Distance

|

Creates a clipping plane at the offset

distance from the selected entity.

|

|

Save

|

Saves the current clipping plane, and

keeps it available for the active study.

|

|

Create

|

Creates a new clipping plane.

|

|

Clipping Plane on Deformed Model

|

Shows the deformed model on the

clipping plane. When this option is cleared, the

original undeformed model is shown.

|

|

| Max |

Specifies

the maximum value of the results shown on the active plot. |

| Min

|

Specifies

the minimum value of the results shown on the active plot. |

Animation

You can animate the warp results plots. Use the available tools to control the animation speed, pause, stop, or loop the animation.

Report Options

| X-Y

plot

|

Creates a graph of analysis results at selected mesh

nodes. Use Measure

(SOLIDWORKS Plastics

CommandManager) to select nodes on the part at locations of

interest. The selected nodes are listed under

Node List. Node

numbers indicate the order of selection.

The graph in the right window displays the result value for each

node. The software assigns numbers to the Curve points in the order

in which you select the nodes. You can select any

of the available results to update the graph with the selected

nodes.

|

| Results Adviser |

Activates the Results

Adviser panel. The top window

provides a brief interpretation of the simulation results,

including any defects, such as short shots, which might have

occurred during filling. It also provides recommendations for

geometry and process parameters changes to improve the product

quality.

At the top of the panel, an icon

of a traffic light indicates the likelihood of the part filling

successfully, based on the value of the injection pressure

relative to the machine injection pressure limit.

- Green: The injection pressure is 66% or

less of the specified machine injection pressure

limit.

- Yellow: The injection pressure is 66%

to 90% of the specified machine injection pressure

limit.

- Red: The injection pressure is 90% or

more of the specified machine injection pressure

limit.

The lower window describes the

active result quantity.

|

| Export

to eDrawings |

Exports the result plot to an

eDrawings file format (*.EPRT). |