A bearing connector simulates the interaction between a shaft and

a housing through a bearing. To define a bearing connector, you must model the

geometries of the shaft and the housing.

You can define a bearing connector between split cylindrical faces of a

shaft, and cylindrical or spherical faces of a housing.

The surfaces of a shaft and a housing that are connected to a bearing

connector can deform relative to each other. The level of relative deformation between

the shaft and the housing surfaces depends on the user-defined connector stiffness.

Type

|

Bearing

|

|

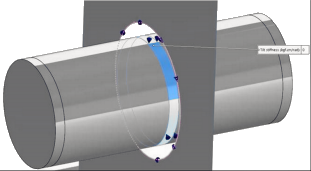

|

For shaft: Cylindrical Face

|

Select a full cylindrical face or

concentric cylindrical faces of smaller angles adding up to 360o. This selection

corresponds to the part of the shaft resting on the bearing.

Create split lines to ensure that the

bearing connector is only defined on the proper faces of the

shaft. You can make the model excessively stiff, if you

select the entire face of the shaft.

|

|

For

housing: Cylindrical face or circular edge of shell

|

Select a cylindrical face,

spherical face, or a circular shell edge (if the housing is modeled

with shells). This selection corresponds to the part of the housing

resting on the bearing. |

| |

|

|

Connection Type

|

Distributed

|

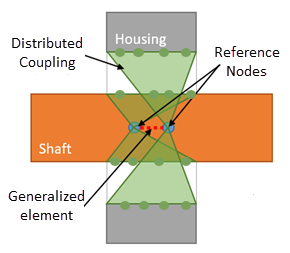

A bearing connector modeled

with the Distributed

type connects the reference nodes of a two-node generalized

element to a group of coupling nodes on the surfaces of the

shaft and housing. One reference node (located at the centroid

of the solid shaft section that is resting on the bearing)

connects to the outer surface of the

shaft.

The second reference node (located at the

center of the housing section that is resting on the bearing)

connects to the housing internal faces. A generalized element

connects the two reference nodes, as shown in the following

image.

Distributed

coupling constrains the motion of the coupling nodes to the

translation and rotation of the reference node. Distributed

coupling allows the coupling nodes on the selected geometry

(shaft or housing) to move relative to each

other.

|

|

Rigid

|

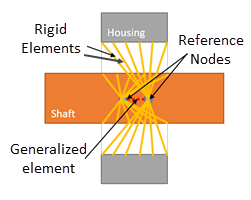

A bearing connector modeled with the

Rigid type has a

similar

formulation with a Distributed type connector.

The only difference for the rigid formulation is that

individual two-node rigid elements connect the reference

nodes to the coupling nodes on the surfaces of the shaft and

housing, as shown in the following image.  The coupling nodes on the selected geometry

(shaft or housing) do not move relative to each other.

|

|

Spring

|

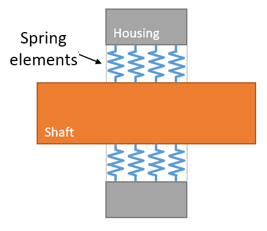

A bearing connector modeled with the

Spring type is

represented with spring elements distributed radially

between the surface nodes of the shaft and the housing, as

shown in the following image.  These local springs provide resistance to

off-axis rotations of the shaft.

|

Connector Stiffness

This section refers to the stiffness applied between the two

reference nodes of a generalized element and also refers to the stiffness applied to

the individual springs for the Spring type.

Each reference node of the two-node generalized element has six

degrees of freedom. You can set the lateral, axial, torsional (optional), and tilt

stiffness (optional) values of the bearing connector in this section.

|

Units

|

Specifies the required unit

system. |

| |

Rigid (infinite stiffness)

|

|

Distributed and

Rigid

Connection Type

|

Applies very high stiffness values to

the reference nodes of the generalized element.

|

|

Spring Connection Type

|

Applies very high stiffness to the

individual springs that are distributed radially between

the selected faces of the shaft and the housing.

|

The selected face of the shaft cannot translate

laterally or axially.

|

| |

Flexible

|

|

Distributed and

Rigid

Connection Type

|

Specifies finite axial and lateral

stiffnesses to the reference nodes of the generalized

element. The selected face of the shaft can translate

laterally or axially according to the defined

stiffnesses.

|

|

Spring Connection Type

|

Specifies the stiffness of the springs

that are distributed radially between the selected

cylindrical faces of the shaft and the housing.

|

You can define total stiffnesses for the lateral

and axial direction for connectors with the Distributed or Rigid type, and distributed

radial (per unit area) and distributed axial stiffnesses (per

unit area) for connectors with the Spring type.

|

Lateral

Lateral

|

Applies the lateral stiffness of the

shaft, k, which resists displacement along the direction

of the applied load. For a

Spring

connection type, the total stiffness K resisting the

lateral displacement of the cylindrical face of the

shaft (along the direction of the applied load)

relates to the radial stiffness per unit area with

the equation: K(total lateral) = 0.5 *

k(radial / unit area)

* Area

Area = diameter * height *

Pi

|

|

Axial

Axial

|

Applies the axial stiffness, k(axial), which resists

displacement along the axis of the shaft.

|

|

|

Tilt

Stiffness |

Tilt stiffness is available for

the Distributed and

Rigid connection type. Applies a tilt stiffness to the reference nodes

of the generalized two-node element to resist the bending of the

shaft.

To recreate the Allow Self-alignment option,

which was available in releases before 2024, set the Tilt stiffness to

zero.

|

| |

Stabilize shaft rotation

|

Select this option to prevent

rotational instability of the shaft (caused by torsion) that can

lead to numerical singularities. You can accept the default

Automatic option or

apply a user-defined torsional stiffness. The

Automatic option

applies a minimal torsional stiffness to the shaft's cylindrical

face that provides circumferential resistance against

torsion.

This prevents the shaft from

rotating freely about its axis and eliminates

instability.

|

Symbol Settings

| |

Edit Color

|

Select a color for the

symbols. |

|

Symbol size

|

Set the size of the symbols.

|

| |

Show preview

|

Toggles the display of the

connector symbols in the graphics area. |

Notes

- Available for static, frequency, linear dynamic, and

buckling studies. Not available for composite shells.

- Use the Split Line

tool to define the cylindrical faces for the shaft that are resting on the

bearing. For example, use the Split

Line tool to create the following highlighted face to apply

a bearing connector.

- To define a bearing connector between a solid shaft surface

and a circular shell edge housing, set the Connection Type to Rigid, as shown in the example below.

-

When to use a Bearing Connector A

bearing fixture assumes that the components supporting the shaft are much

more rigid than the shaft and can be considered as fixed to the ground. When

this assumption is not valid and the flexibility of the supporting parts

must be included, you should use a bearing connector formulation to simulate

the connection. You need to model not only the shaft but also the housing.

In the example shown below, the bearing connectors are

defined between the cylindrical split faces of the shaft and the

spherical faces of the housing.