The Tsai-Wu criterion is applied to determine the factor of safety for composite orthotropic shells.

This criterion considers the total strain energy (both distortion energy and dilatation energy) for predicting failure. It is more general than the Tsai-Hill failure criterion because it distinguishes between compressive and tensile failure strengths.

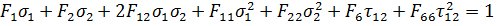

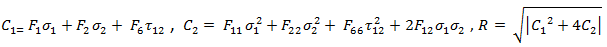

For a 2D state plane stress (σ3 = 0, τ13 =0, τ23 =0), the Tsai-Wu failure criterion is expressed as:

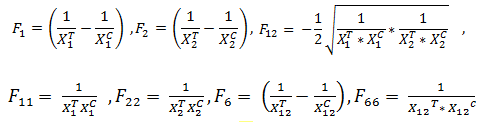

The coefficients Fij of the orthotropic Tsai-Wu failure criterion are related to the material strength parameters of the lamina and are determined by experiments. They are calculated from these formulas:

| XT1 |

tensile material strength of laminate along fiber direction |

| XC1 |

compressive material strength of laminate along fiber direction |

| XT2 |

tensile material strength of laminate transverse to fiber direction |

| XC2 |

compressive material strength of laminate transverse to fiber direction |

| XT12 |

positive shear strength of laminate |

| XC12 |

negative shear strength of laminate (the solver considers it equal to the positive shear strength) |

The stress state of the lamina calculated by the program is described by the components: σ1, σ2, and τ12

| σ1 |

laminate stress along fiber direction |

| σ2 |

laminate stress transverse to fiber direction |

| τ12 |

laminate shear stress |

Composite Ply Material Directions

Direction 1 refers to the ply fiber orientation direction.

Direction 2 refers to the transverse fiber direction in the plane of the ply.

Factor of Safety

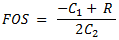

The program reports the factor of safety (FOS), which is the coefficient by which all laminate stress components should be multiplied to reach laminate failure according to the Tsai-Wu criterion stated above. The FOS for laminate failure is calculated from:

, where the coefficients are given by:

, where the coefficients are given by:

A factor of safety larger than 1.0 indicates that the laminate is safe from failure.

The Tsai-Wu failure criterion cannot predict different failure modes including fiber failure, matrix failure, and fiber-matrix interface failure.