You can use the Underconstrained

Bodies tool to detect any rigid (or free) body modes of bodies that are not

adequately supported by fixtures, connectors, or bonded interaction conditions.

To detect underconstrained bodies, do one of the

following:

- From a static study tree, right-click Connections

and click Underconstrained Bodies

and click Underconstrained Bodies

.

.

- From the CommandManager, select Diagnostic Tools, and click Underconstrained Bodies

.

.

- From the dialog box, select Automatically

detect underconstrained bodies.

As a best practice, before you run the Underconstrained Bodies tool, define realistic materials, loads,

and boundary conditions for your model. The study properties should reflect, as

accurately as possible, the operating loads and boundary conditions of the model you

are trying to analyze.

For each part of an assembly, the algorithm checks for free

translations and rotations in the global X, Y, and Z direction and also in oblique

directions. It is also able to detect instability issues in assemblies with chain

(or hinge) mechanisms between parts. In cases where free body modes are detected,

the Underconstrained Bodies tool animates

them accordingly.

The detection of underconstrained bodies is based on the

transformation of the stiffness matrix associated with a finite element model to a

reduced-size stiffness matrix (typically with three translational and three

rotational degrees of freedom per body). The underconstrained modes of the reduced

system are equivalent to the original system of equations.

The transformation of the global stiffness matrix to a reduced-size

stiffness matrix is completed by:

- Introducing a single representative node (reference point)

with six degrees of freedom for each body that represent the translational

and rotational motion of each body

- Transforming the element stiffness matrices by replacing the

original degrees of freedom with the degrees of freedom of the

representative nodes

- Assembling the transformed element stiffness matrices to

determine the reduced-size stiffness matrix

Advantages

The solution is much faster. The performance improvement is based on

the adoption of the Singular Value Decomposition (SVD) technique that is performed

over the reduced stiffness matrix. The reduced stiffnesses are calculated from the

interface surface interaction between bodies originating from boundary conditions,

bonded and contact interactions, or connectors.

The following is an example of a reduced stiffness matrix:

|

|

|

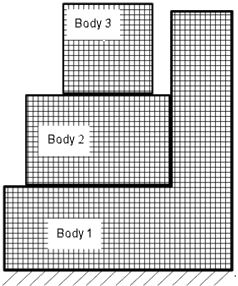

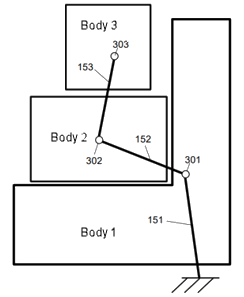

| Each body reduces to one reference point in

the stiffness matrix. The global stiffness matrix reduces from

hundreds of thousands of degrees of freedom to only 18 (3 bodies

x 6 degrees of freedom). |

The method considers stiffnesses that

originate from the interactions between bodies. Bodies 1 and 2

come into contact, so the method considers the effect of their

stiffnesses between their reference points. The method considers

stiffnesses that originate from boundary conditions as well, for

example, the stiffness between Body 1 and the ground. |

The SVD technique decomposes the reduced stiffness matrix to three

matrices.

The U and V vectors are orthonormal to each other and describe the

shape of the displacement field. The middle matrix is a diagonal matrix. The

diagonal terms represent the relative stiffnesses of the links between the bodies or

between a body and the ground. If any of the diagonal terms is zero or close to

zero, then this is an indication of a rigid body mode.

You can view animations of the unconstrained displacements of the

whole assembly.

You can view animated translations or rotations in oblique

directions.