The Pack analysis module simulates the conditions inside the cavity

before

part ejection.

SOLIDWORKS Plastics simulates the material’s phase change from fluid to solid

and the volumetric shrinkage that results. It also simulates the build-up of stresses,

which later influence the molded plastic part’s final dimensions and

warpage. Pack results

are required to run a Warp analysis.

Pack analysis simulates the process where an injection machine applies pressure

to the injection system to cause additional material to enter the cavity as the part

shrinks and freezes. To control the switch-over from Fill to Pack, you can specify a

time value or a cavity fill percentage in the Pack

Settings PropertyManager. You can also use these settings to create a

pressure profile rather than using a constant packing pressure.

Results from a Pack analysis include:

- Distributions of temperature time histories at every

location

of the part, which allows the prediction of hot spots, gate freeze, and cycle

time

- Distributions of pressure, residual stress, and volumetric

shrinkage

- Information about the required clamping force and the

time-evolution of the part mass as the material density changes.

From the Fill and Pack analyses, you can estimate the optimal process

conditions, such as filling time, injection pressure profile, pressure holding time,

melt temperature, and mold temperature. In addition, you can gain insights about the

optimal mold design parameters such as gate location, gate design, and runner

design.

Pack Analysis Steps

| 1 |

Define the process parameters:

- Pack time, pressure profile

- Pure cooling time

|

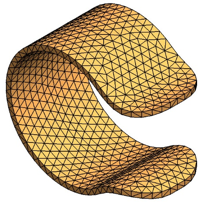

CAD geometry of a

part |

| 2 |

Create the mesh and select

materials |

Surface mesh

|

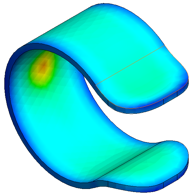

| 3 |

Run the analysis |

Result plot of volumetric shrinkage at end of

packing

|