A mesh subdivides each domain of the simulation model, the cavity, runner

system, cooling channel, inserts, and mold, into discrete cells.

Within each cell, the software applies the appropriate conservation equations. The

conservation equations compute the flow of melted polymer and heat, simulate phase

change as the melt cools, and predict residual stresses and their effect on the

unconstrained part shape.

The solid and shell analysis procedures require mesh definitions for the

computation. The mesh requirements differ for each procedure.

|

Shell Analysis Procedure

|

The shell analysis procedure is a simplification for thin parts, based on a

Hele-Shaw type flow approximation. The analysis procedure uses a proprietary

binary-plane discretization approach, the basis of which is a triangular

surface mesh. The software does not create a part volume mesh, and the mesh

is classified as a shell mesh.

|

|

Solid Analysis Procedure

|

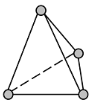

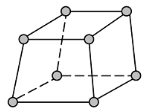

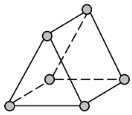

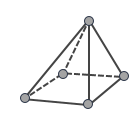

The solid analysis procedure subdivides the volume of each domain into

polyhedral-shaped elements. The software generates these elements

automatically. These solid elements might have one of four shapes:

tetrahedral, hexahedral, prismatic, or pyramid. The required mesh for this

analysis type is classified as a solid mesh. The software

still creates a surface mesh, as in the surface mesh procedure, but the

surface elements (faces) effectively represent the boundaries of the

enclosed solid polyhedral elements.

|

|

|

|

|

| Tetrahedral Element |

Hexahedral Element |

Prismatic Element |

Pyramid Element |

When creating a plastics study, the choice of analysis procedure determines the

selection of the appropriate mesh type.