|

|

Melt

Temperature (°C) |

Specifies the temperature of the

polymer at the injection

location.

The default value for Melt Temperature is taken from

the material database (see the Polymer-Material Parameters tab of the selected

material).

Click Reset

to reset the

Melt Temperature to

its default value. to reset the

Melt Temperature to

its default value.

|

|

|

Mold

Temperature (°C) |

Specifies the temperature that the

mold is heated to. The default value for

Mold Temperature is

taken from the material database.

Click

Reset

to reset the

Mold Temperature to

its default value. to reset the

Mold Temperature to

its default value.

If the

mold temperature is not constant but varies with time,

select Mold Temperature

profile to enter the mold temperature

data.

|

| |

Filling Time |

Specifies the time it takes the

molten plastic to fully fill the cavity. The

program calculates the Filling

Time automatically based on the part geometry

and the properties of the material you select.

Click Auto

to enable

editing of the Filling

Time. to enable

editing of the Filling

Time.

If you use the

Advanced options

below to control the filling process, SOLIDWORKS Plastics

recalculates the Filling

Time.

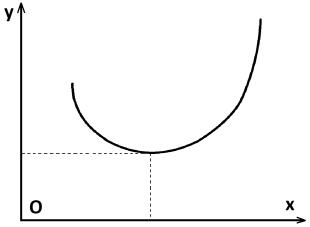

The following

graph shows the variation of injection pressure (y-axis) with

respect to filling time (x-axis). The optimal filling time is

located at the bottom of the curve. For short or very long

filling times, higher injection pressure values are required.

|

|

Injection Pressure Limit

|

Specifies the maximum allowed

value of the pressure of the polymer at the injection location (or

locations). If the pressure reaches the

Injection Pressure

Limit value, the inlet flow rate automatically

reduces to a value corresponding to this limit, and the

Filling Time is

longer than the requested value.

You can

adjust the default Injection

Pressure Limit according to the capacity of your

machine.

Click Reset to reset the Injection Pressure Limit to its

default value.

|

|

Fill/Pack Switch Point (%

Filled Volume)

|

Controls the process changes from Fill to Pack. During Fill, polymer is forced into the cavity

at a given flow rate, regardless of pressure. To avoid a rapid

pressure rise and potential damage to the machine, it is common

to switch from Fill to Pack just before the cavity becomes full,

for example at 95% of the cavity volume.

|

|

|

Temperature Criteria for Short Shots (°C) |

If the temperature in the molten polymer is

below this temperature value, a warning appears in the

AnalysisManager.

If the temperature stays below this value for

several iteration steps, a short-shot occurs. The polymer

solidifies and the melt flow stops.

|

| |

Multi general Gate Flow-rate/Press control

|

|

Equivalent

|

Distributes equal flow rates at each

injection location, with potentially different resulting

pressures.

|

|

Automatic

|

Balances the flow between injection

locations to produce equal pressures, simulating the

effect of a runner system.

|

Available for a shell analysis procedure with multiple

injection locations. |

|

Flow

Rate Profile Settings

|

Controls the flow rate during the

filling of the cavity by defining a Flow

Rate Profile based either on volume or time control.

See Injection Unit Settings - Flow Rate Profile Settings.

|

| |

Mold Temperature

Profile

|

Defines the mold temperature

variation for cases where the mold temperature is not constant. See Injection Unit Settings - Mold Temperature Profile.

|

| |

Viscoelastic Birefringence

Calculation |

Activates the Birefringence calculation. To use this option,

apply a polymer that includes definitions for the Birefringence

material parameters.

These material parameters are the Leonov parameters in listed in

the Material database.

|