Enhanced algorithms automatically bond touching entities for the following cases:

- A face or edge of a shell with a solid.

- A face or edge of a shell with another face or edge of shell.

- A face of a solid or shell with a beam that acts as a stiffener.

The beam's body should touch the solid or shell face.

- A face of a solid or shell with a beam joint.

Sheet metal bodies and surfaces mesh with shells. You can apply loads, fixtures,

interactions, and connectors to sheet metal bodies and they get transferred to the

mid-surface automatically. See also Applying Loads and

Restraints to Shells.

To view or edit the shell edge to faces contact definitions, use the option

Find shell edge - solid/shell face pairs in

the Local Interactions PropertyManager.

For touching faces of sheet metal components that mesh with shells created at mid-surfaces, the program transfers the bonding contact to mid-surface shells automatically.

This limitation applies only to (a) the node-to-surface bonding

formulation for all studies, and (b) the surface-to-surface bonding formulation for

nonlinear studies.

In cases where bonding contact exists between sheet metal parts

with other surfaces (solids or shells), the bonding algorithm can enforce

over-stiffening due to the gap between the mid-surface mesh and the contact surface

geometry. The over-stiffening of the bonding contact alters the calculation of the

rigid body modes. The program will calculate all rigid modes (with frequency values

close to 0), if you eliminate the gap by offsetting the mesh of the sheet metal

parts from the mid-surfaces to the contact surface geometry.

|

|

| Surface edge touching a sheet metal face

|

Side view of mesh (zoomed) |

|

|

| Sheet metal faces touching each other

|

View of Mesh at Mid-Surfaces

|

|

|

| Solid face touching a sheet metal face

|

Side view of mesh (zoomed)

|

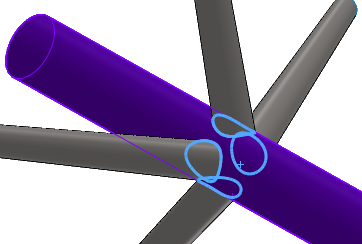

Bonding between touching structural members with a sheet metal face is also automatically created and transferred to mid-surface shells.

|

|

| Structural members touching a sheet metal face |

Side view of mesh (zoomed)

|

You need to manually define bonding for touching non-planar faces that mesh with shell elements. However, automatic bonding occurs for touching edges of surfaces with non-planar faces.

|

|

| Automatic detection of contact sets between solid and shell bodies that intersect at spline surfaces. Use option Find shell edge - solid/shell face pairs. |

Touching non-planar faces of shells. Set the bonded contact manually. |

When beam joints are connected to a neighboring face of a solid or shell, the

beam’s actual cross-section is meshed and imprinted on the solid or shell face, creating

a more accurate bonding

connection.

During meshing, elements are created in the imprinted beam section area. The end

beam joint is connected to all elements inside the imprinted section area forming a more

realistic representation of the

joint.

|

|

| Beam-plate joint |

Mesh of the imprinted beam section area on the plate

|

This more realistic formulation of the beam joint - plate bonding connection is not currently available for nonlinear studies. To solve a nonlinear study with beam joint - plate connections, you need to create a new mesh. You cannot copy the existing mesh from a static study to a nonlinear study.