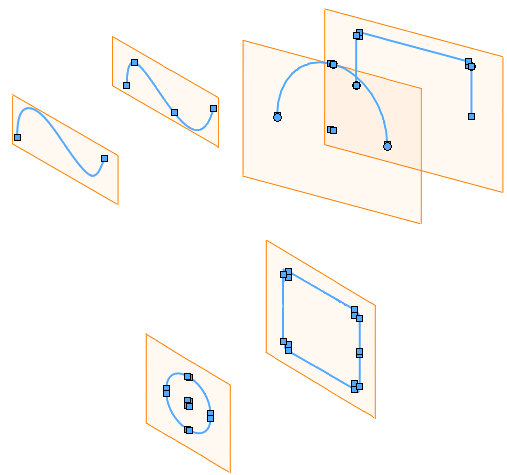

Lofted bends in sheet metal parts use two open-profile sketches that are connected by a loft. The Base-Flange feature is not used with the Lofted Bend feature.

|

|

| Begin with two open profile sketches. |

Use Lofted Bends to create a solid feature. |

|

| Lofted bend is complete. |

Characteristics of lofted bends:

- Cannot be mirrored.

- Require two sketches that include:

- Open profiles without sharp edges.

- Aligned profile openings to ensure flat pattern accuracy.

- Profile segments in each sketch are the same type.

It is not necessary that the sketches be on parallel planes. However, bend lines appear in the flat pattern only when the sketches are on parallel planes. Bend lines are valid and applicable to lofted bend geometry that can be manufactured by the incremental brake press method.

- K-factor applies to flat patterns of lofted bends only if the lofted bends are created from sketches that meet the following conditions:

- The planes of the two sketches are parallel.

- The sketches have an equal number of linear and non-linear segments

- For each linear sketch segment in the first sketch, there must be a corresponding parallel sketch segment in the second sketch

- For each non-linear sketch segment in first sketch, there must be a corresponding non-linear sketch segment in the second sketch whose end tangents must be in the same direction as the first sketch’s non-linear segment.

Valid sketch pairs where K-factor is applied:

Invalid sketch pairs where K-factor is not applied: