You can create complete

inspection reports using existing SOLIDWORKS part and assembly files (*.sldprt and *.sldasm).

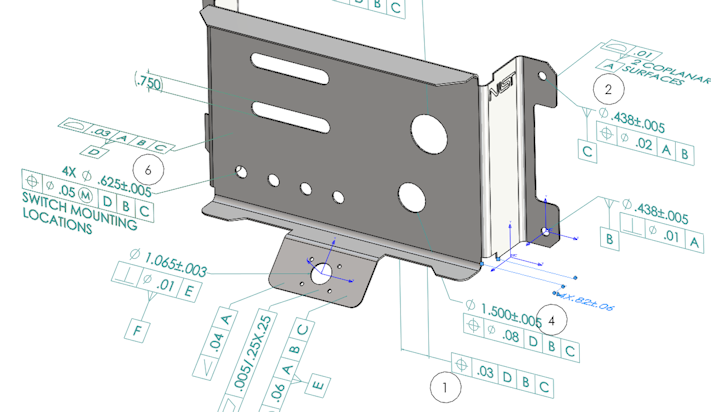

When you open a SOLIDWORKS part or assembly that contains 3D annotations

or Product and Manufacturing Information (PMI), you can create a new inspection project

and extract all the information for the inspection checklist.

To create an inspection report from a SOLIDWORKS part

or assembly:

- Click New Inspection Project

(CommandManager).

- Select project settings and extraction settings.

Use the check boxes to set up the project. For example, you can include or

exclude Dimensions, Notes,

GD&Ts, and Hole Callouts,

SOLIDWORKS Inspection then adds the balloons to the PMI. Quality inspectors can then

refer to the inspection spreadsheet and the 3D model to understand which characteristics

to inspect.

You can use either Automatic or

Manual extraction mode.

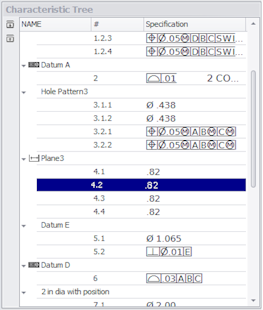

The Inspection characteristics are listed in the Characteristic Tree. You

can modify the properties of a characteristic to include additional information such as

Operation, Classification, and Method of Inspection. Additionally, you can reorder

them.

When the project is complete, you can generate:

- Microsoft® Excel report

- 2D PDF

- 3D PDF (if SOLIDWORKS MBD is available)

- eDrawings file