A Spring

connects parallel planar faces or

concentric cylindrical faces with springs that can resist tension only (cables), compression

only, or tension and compression.

connects parallel planar faces or

concentric cylindrical faces with springs that can resist tension only (cables), compression

only, or tension and compression.

Spring connectors for surfaces and sheet metal bodies are available

for static, frequency, dynamic, and buckling studies. The feature is not available

for composite shells. For nonlinear studies, define connectors between two vertices

or reference points only.

Type

|

Compression Extension

|

Resists tension and compression.

Available for static, frequency, buckling, and nonlinear studies.

|

|

Compression only

|

Resists compression only.

Available for static and nonlinear studies. |

|

Extension only

|

Resists tension only. Available

for static and nonlinear studies. |

| |

Flat parallel faces

|

|

Planar Face or Edge of Component 1

Planar Face or Edge of Component 1

|

Planar faces or edges of shells from a

body. Edges of shells refer to

edges of surface bodies and the face containing the

smallest dimension for sheet metal bodies. The

program meshes the sheet metal bodies with shell

elements and converts the face of the sheet metal

containing the sheet metal thickness into an edge.

|

|

Parallel Face or Edge of Component 2

Parallel Face or Edge of Component 2

|

Planar faces from another body or edges

of shell. These faces should be parallel to the faces

selected above. If you selected linear edges for both

selections, they should be straight and parallel to the

edges selected above.

|

|

| |

Concentric cylindrical faces

|

|

Cylindrical Faces of Component 1

Cylindrical Faces of Component 1

|

Cylindrical faces or circular edges of

solids or shells.

|

|

Cylindrical Faces of Component 2

Cylindrical Faces of Component 2

|

Cylindrical faces or circular edges of

shells from another body. These faces or edges should be

concentric to the faces or edges selected above.

|

|

| |

Between vertices

|

|

Vertex or point for first location

Vertex or point for first location

|

|

|

Vertex or point for second location

Vertex or point for second location

|

Select a vertex or a reference point

from the same or different component or a body.

|

|

Symbol Settings

| |

Edit Color

|

Select a color for the

symbols. |

|

Symbol size

|

Set the size of the symbols.

|

| |

Show preview

|

Toggles the display of the

connector symbols in the graphics area. |

Tips

- Springs are introduced in the common area of projection of

the faces from one body on the faces from the other body. If there is no

common area, the software cannot create the spring.

If

you selected an edge of a shell from a body and face of a solid or edge

of a shell from another body, springs are introduced along the common

length of projection of the edges from one body to edges or faces of

another body.

- You can split one or both faces by projecting one face onto

the other. Define a spring between the new, aligned faces.

- When viewing results, plot the deformed shape with 1.0

scale factor to ensure that there is no interference between components.

When interference occurs, the results are not valid. Define contact

conditions between the interfering faces before re-running the study.

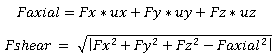

- When listing spring connector forces, the axial and shear forces are

computed based on the relations:

Where Fx, Fy, and Fz are the spring forces with respect to the global

coordinate system, and u = {ux, uy, uz} is the unit vector positioned along the

spring. A negative axial force indicates a spring in compression, whereas a positive

axial force indicates a spring in tension.

When a spring connector is applied between flat or cylindrical

faces, the software lists the spring forces as the sum of the individual spring

elements connecting the two faces.