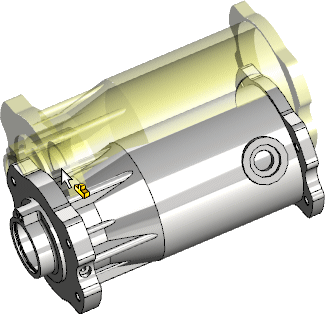

Aside from setup costs, the cost of the material removed during finishing operations determines the cost of the finishing operations. Next, you define a multibody part for the material removed during post-machining operations.

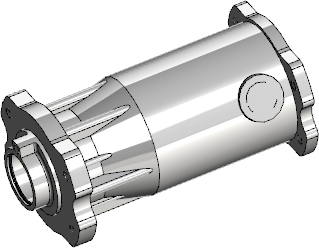

One way to define a multibody part for the removed material is to subtract the stock body for the cast part from the finished part. What remains is the volume of material removed during the post-machining operations.

- From the ConfigurationManager

for my_cast_cylinder.sldprt, right-click Default [ my_cast_cylinder ] and click Add Derived Configuration.

for my_cast_cylinder.sldprt, right-click Default [ my_cast_cylinder ] and click Add Derived Configuration.

- In the PropertyManager, for Configuration name, type Costing Example, and click

.

.

- Add the stock part to the finished part:

- Click .

- Select install_dir\samples\whatsnew\costing\cast_part_volume_removed\CAST_CYLINDER_STOCK.SLDPRT, and click Open.

- Drag the stock part to the finished part and click the bodies when they match up.

- Click .

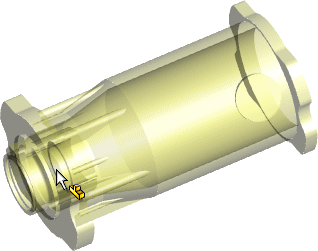

- In the PropertyManager, for Operation Type, select Subtract.

- Subtract the two bodies to define the part for the volume of removed material:

- In the FeatureManager design tree, expand Solid Bodies (2).

- For Main Body, select <CAST_CYLINDER_STOCK>.

- For Bodies to Subtract, select Flange Holes, and click

.

.

- In the Bodies to Keep dialog box, select All bodies, and click OK.