| Maximum von Mises stress

|

σlimit / σvonMises |

Ductile

|

| Maximum shear stress

|

σlimit / (2 * τmax) |

Ductile

|

| Mohr-Coulomb stress

|

- σ1 > σ 2 >

σ3,

If (σ1> 0 and σ3 > 0)

then (σ1 ≥ σTensile Limit)

If (σ1< 0 and σ3 < 0)

then (|σ3| ≥ σCompressive Limit)

- If (σ1> 0 and σ3 <0)

then (σ1 / σTensile Limit + |σ3| / σCompressive Limit ≥1)

When the third principal stress σ3 is in compression

(negative), both values for σ3 and the material's compressive limit have

positive signs for the FOS

calculation.

|

Brittle materials with different tensile and compressive strengths

|

| Maximum normal stress

|

σlimit / σ1 |

Brittle

|

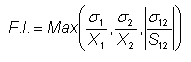

| Maximum stress criterion (composites)

|

FOS = 1/F.I.

|

Brittle

1 and 2 stand for material directions. X and S are normal and shear strengths of the composite.

|

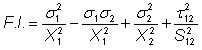

| Tsai-Hill Failure criterion (composites) |

FOS = 1 / SQRT (F.I.)

|

Brittle

|

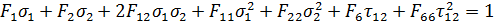

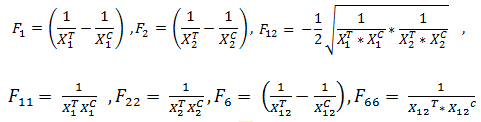

| Tsai-Wu Failure criterion (composites)

|

|

Brittle

|