The Cool analysis module performs heat transfer analysis to obtain the

transient

temperature

distribution

occurring within the

mold during the injection

molding

cycle.

The Cool analysis encompasses the mold, the cavity, and the cooling system within the

mold. Temperature changes occur slowly compared to the speed at which the cavity

fills.

SOLIDWORKS Plastics makes an approximation that allows running the Cool

analysis first, separately from the Fill analysis module. It stores the transient

temperature results from the Cool analysis in a database for use in subsequent Fill and

Pack simulations.

To simplify the problem, you can

skip

the Cool analysis, and enter mold temperature data as a single uniform value for the

entire cavity surface using the Fill Settings

PropertyManager. You can also select surfaces and specify their temperature values using

the Mold Wall Temperature boundary condition.

Cool Analysis Steps

| 1 |

Define the process parameters:

- Cooling channels geometry

- Mold dimensions

- Melt temperature

- Coolant temperature and Flow rate

profile

|

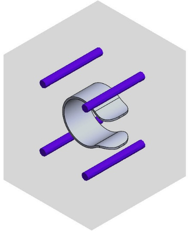

CAD geometry of a

mold, cooling channels, and part |

| 2 |

Create the mesh and select

materials |

Surface mesh

|

| 3 |

Run the analysis |

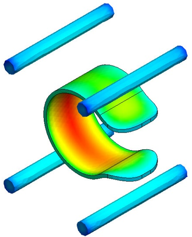

Result plot of average mold temperature at the

end of cooling

|