The Nominal Wall Thickness Advisor queries the geometry and determines the overall nominal wall thickness in the model and the percentage deviation of thickness from this nominal value.

The primary design rule for injection-molded plastic parts is the maintenance of a uniform wall thickness. A uniform wall thickness leads to uniform filling patterns, pressure distributions, cooling times, shear stress, and volumetric shrinkage. Parts with uniform wall thicknesses have optimized cycle times and are less likely to warp or deform out of shape.

To access the Nominal Wall Thickness Advisor, right-click Nominal Wall Thickness, and select Open Adviser.

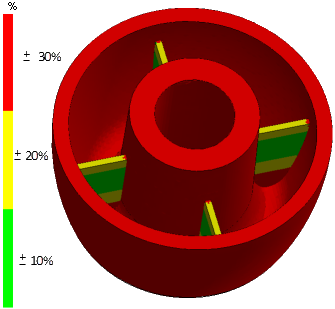

A thickness distribution plot of the part shows the percentage deviation from the nominal wall thickness.