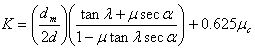

The friction factor is also known as torque coefficient.

The definition of friction factor is given in: Mechanical Engineering Design 5th edition by Shigley and Mischke, Chapter 8-8, pages 345 - 347.

d = major diameter of the screw

dm = mean diameter of the screw

λ = lead angle of the thread; tan λ = p/π dm (where p is the pitch)

2α = thread angle (2α = 29° for Acme threads and 2α = 60° for ISO metric M threads)

μ = friction coefficient for the threads

μc = coefficient of collar friction for the screw head

The coefficients of friction μ and μc depend upon the surface smoothness and the degree of lubrication. Average values for μ and μc are approximately 0.15.

The following table includes typical values for the friction factor

(Bowman Distribution-Barnes Group, Fastener Facts, Cleveland, 1985, page 90). If the bolt condition is unknown, K = 0.20 is recommended.

| Bolt condition |

K |

|---|

| Nonplated, black finish |

0.30 |

| Zinc-plated |

0.20 |

| Lubricated |

0.18 |

| Cadmium-plated

|

0.16 |

| With Bowman Anti-Seize |

0.12 |

| With Bowman-Grip nuts |

0.09 |